Featured projects

Triple railway crossing for fibre optic installation

Date

May 2023

Type of installation

Telecommunications

Pipe

Fibre Optic

Drilling length

3100m

Soil

Class 3 – 5

Location

Niederaußem

Combination of technology and expertise for the triple crossing of a railway line in Niederaußem with the aim of installing eight fibre optic connectivity multi-ducts.

At Catalana Drilling, we enjoy sharing the details behind each of our projects — especially when they represent a real technical challenge and a complete success.

The work carried out in Niederaußem, for Deutsche Glasfaser, is a great example: a demanding project that brought together technology, experience, and planning to install a high-capacity fibre optic network.

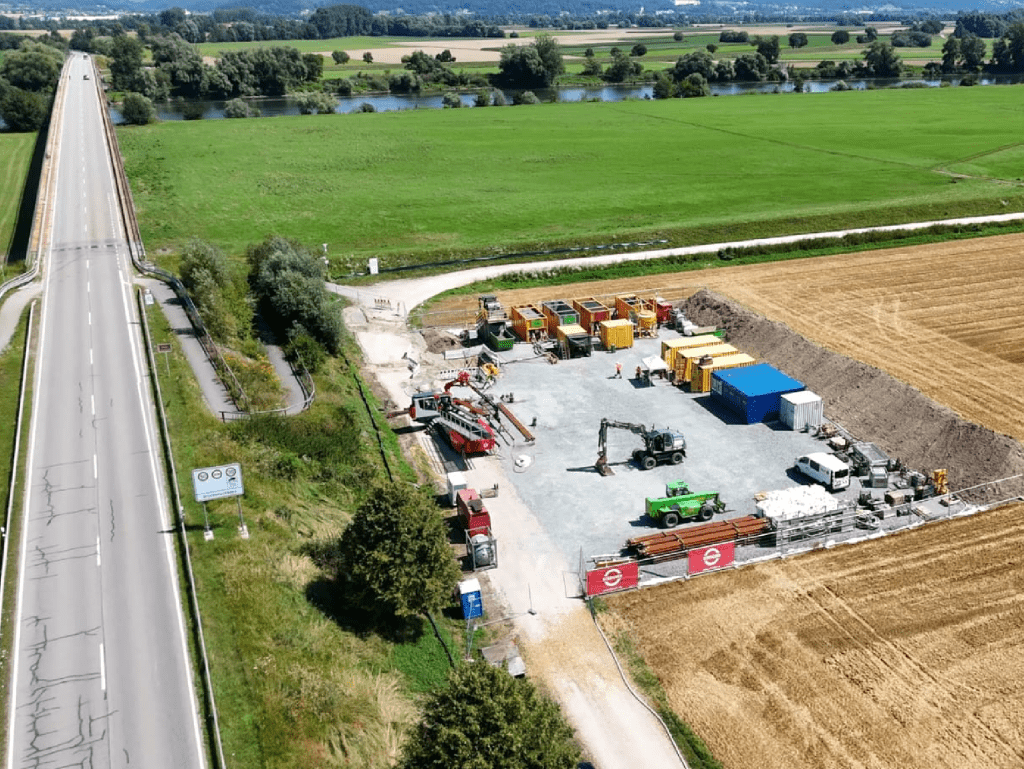

The project involved managing work permits, executing three horizontal directional drillings (HDD) beneath a railway line, and installing eight multiducts designed to house the fibre optic cables. All with the goal of delivering high-speed connectivity and strengthening the region’s telecommunications infrastructure.

A technical challenge

Between 20 March and 17 May 2023, our team worked on ground classified between classes 3 and 5, which required precise planning, adaptability, and solid teamwork.

Prior to construction, detailed geotechnical studies were carried out to design the most suitable drilling strategy and ensure the safe completion of the railway crossing.

The project went beyond the mere execution of the underground crossing — it also involved the installation of 192-fibre cables, ensuring a reliable and high-capacity connection ready to meet the area’s growing digital needs.

What strategy was used to carry out the project?

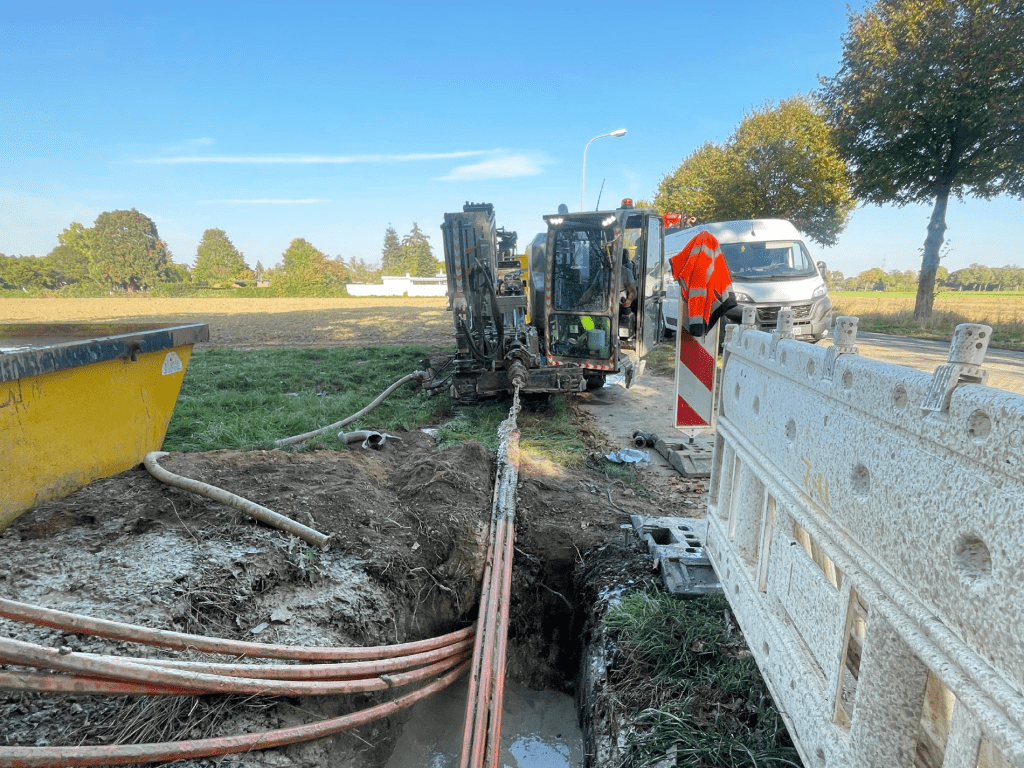

- Horizontal Directional Drilling (HDD): three pilot drillings were carried out to cross under the railway line and install 8 multiducts MD7 x14 Ø 44 mm, guaranteeing accuracy and safety at every stage.

- Fibre optic blowing: the installation of a 192-fibre cable ensured a stable, high-speed connection ready for future expansion.

By combining both methods, the project was completed on schedule and to the highest technical standards.

Less impact, more efficiency

The Horizontal Directional Drilling (HDD) technique was the key to success. This system allows work to be carried out underground without the need for open trenches, avoiding large excavations and significantly reducing environmental impact. As a result, complex underground works can be completed without major disruption to the surface or surrounding infrastructure.

In addition to the triple railway crossing, the project also included complementary works near the power plant, improving local connections and optimising existing infrastructures. All stages were carried out under strict technical and environmental supervision, reinforcing our commitment to sustainable and responsible engineering.

Teamwork at its best

The success of this project was made possible thanks to the close collaboration between the Catalana Drilling team, Deutsche Glasfaser, and the local authorities involved.

Continuous communication, careful coordination, and the experience gained from similar projects allowed us to overcome each challenge and complete the work successfully.

At Catalana Drilling, we remain committed to a collaborative, efficient, and responsible way of working. Each new project is an opportunity to keep learning, innovating, and building infrastructure that connects people and communities — always with respect for the environment.