HORIZONTAL DIRECTIONAL DRILLING

Domènec Pintó

BUSINESS ADMINISTRATOR

WORK PROCESS

Knowing the terrain: the key to any project’s success

Before carrying out any project, we conduct a preliminary drilling study. This helps us reduce risks and plan each step with maximum precision. It also allows us to anticipate possible complications related to the geology of the terrain or the presence of previously installed services such as pipes, electrical cables, fibre optic networks, gas services, etc.

For each intersection, we carry out a comprehensive analysis using technologies such as ground-penetrating radar, which allows us to detect any type of previous installation in the ground.

In addition, through topographic surveys, bathymetry and tomography, we have precise knowledge of the geological characteristics of the subsoil, which helps us in our decision-making.

Each project is unique, which is why we carry out a preliminary selection process to decide on the technique and machinery to be used according to the circumstances and characteristics of the terrain to be drilled. We also avoid unforeseen events during the execution of the project and optimise resources to the maximum, which translates into a better end result and savings in costs and time for the client.

Technical design of the drilling: each intersection is a new challenge

Using the data collected during the preliminary study, our engineering team designs a customised solution for each intersection, analysing all the variables of the terrain and the project: depth, curvature radii, technical restrictions and the presence of previously installed services.

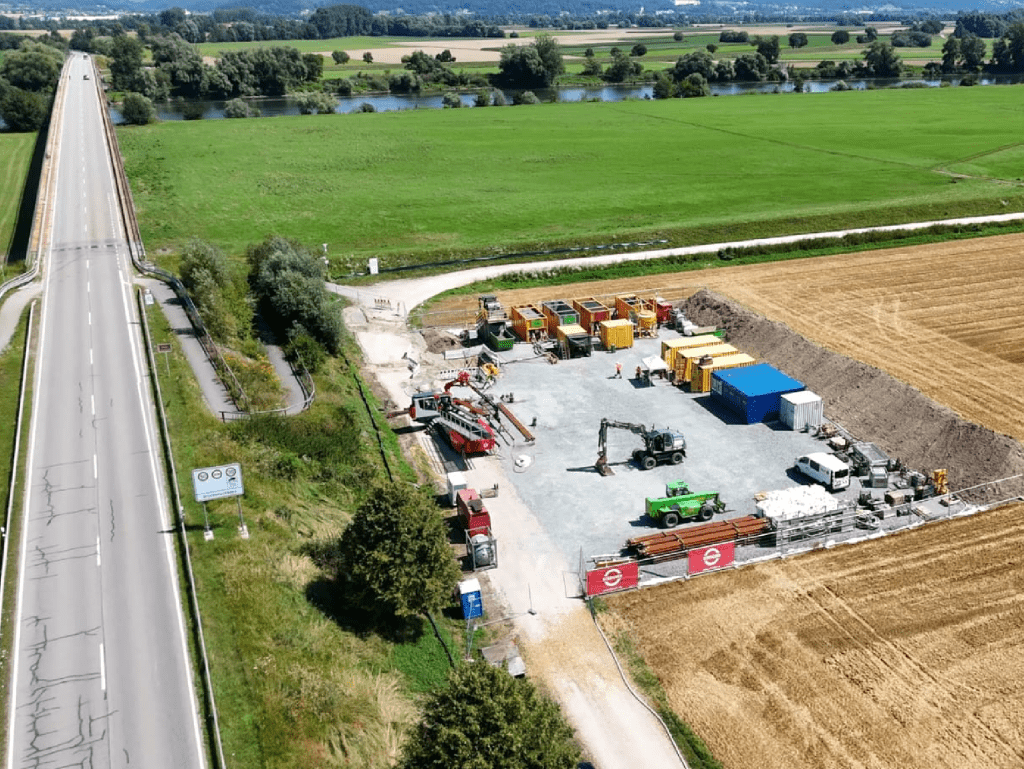

In this phase, we draw up construction plans detailing the location of equipment and machinery, the work area, welding points and underground layout profiles.

Everything is adjusted to ensure the technical feasibility and successful execution of the drilling project.

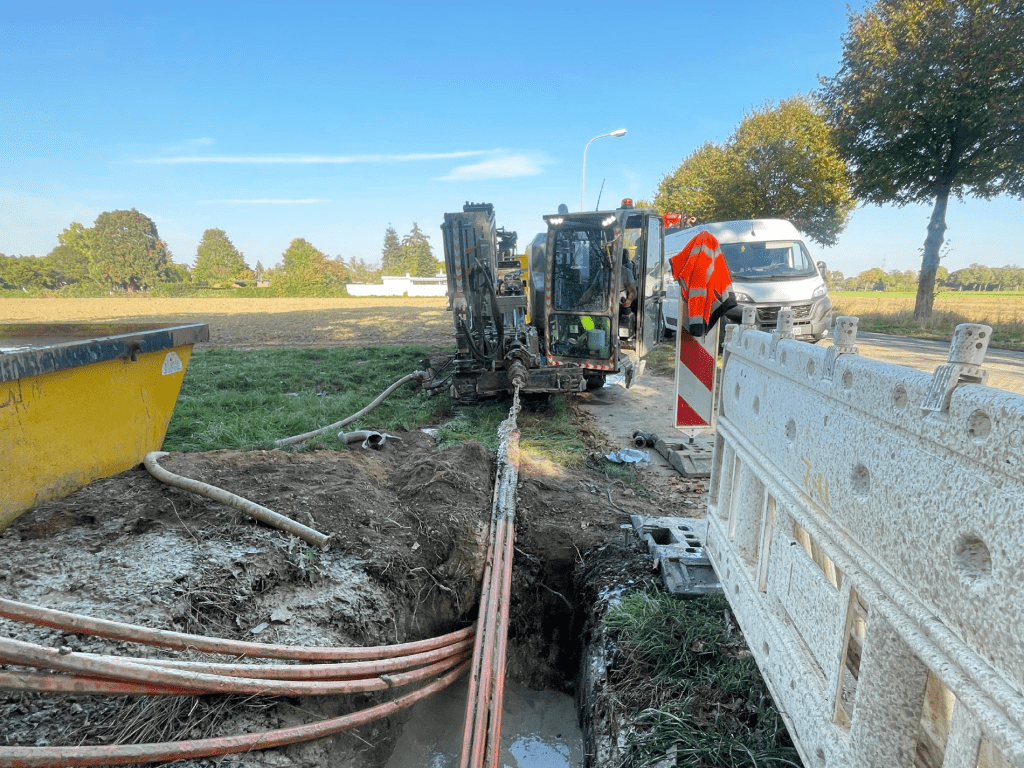

Pilot drilling: start of the layout

Pilot drilling marks the start of the horizontal directional drilling process. This is where our navigators plot the route that the pipe will follow, guiding the drilling machine with high precision using specialised navigation systems.

We have the equipment and qualified personnel to operate different navigation systems such as Walk-Over, Paratrack II and Gyro,

this allows us to adapt to the technical requirements of each project.

Thanks to this technology, we monitor the drilling trajectory in real time, enabling us to correct any deviations on the fly and ensuring an accurate path, aligning the planned entry and exit points.

Widening operation: preliminary step prior to installation

Once the pilot hole has been drilled, it is time to widen the hole.

This process is carried out using specific tools designed to increase the diameter of the hole until it is large enough to install the pipe, adding an additional margin for inserting the tube or pipe.

At Catalana Drilling, we have a wide range of reamers designed to work on all types of terrain, guaranteeing an efficient process adapted to each geological situation.

Pipe installation: precision without interruptions

Pipe installation is a continuous operation that requires precision and coordination.

Installation is carried out from the exit point to the entry point – a process known as reverse traction – and it is not possible to stop the process once it has started.

This method guarantees successful installation of the pipe without damage or blockages, ensuring the quality of the result and the durability of the installation.

Uses

- Essential service networks: electricity, telecommunications, gas and drinking water.

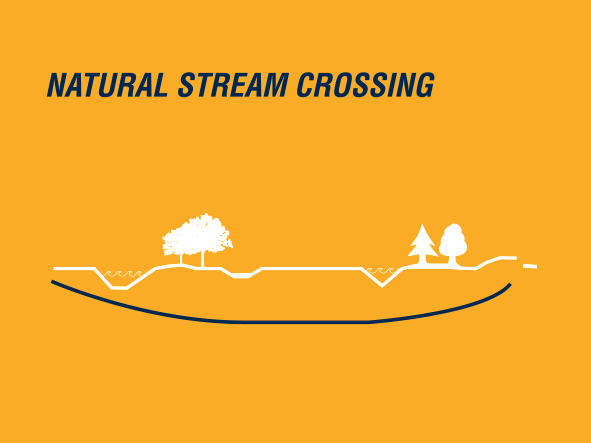

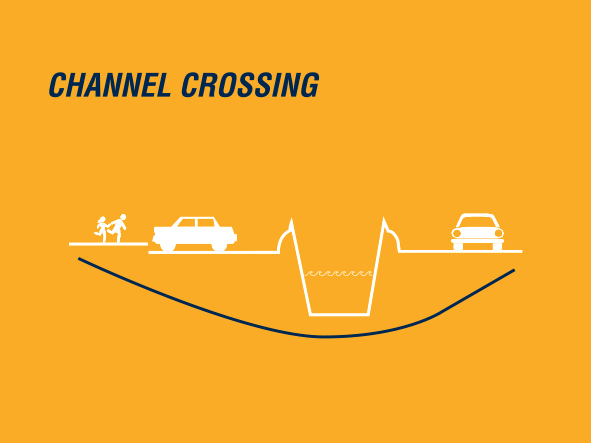

- Intersections with existing infrastructure: roads, motorways, railways, canals, tunnels and urbanised areas.

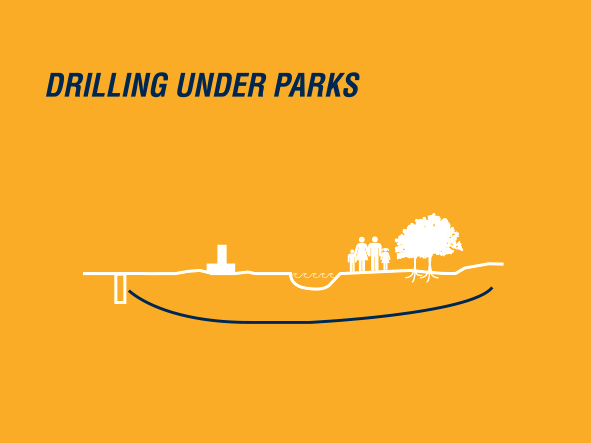

- Complex natural environments: rivers, streams, lakes, natural parks, ravines, slopes and other geological features.

- Sensitive and protected areas: protection of biotopes and areas with environmental restrictions.

- International connections: cross-border intersections and adaptations to the regulations of different countries.

- Renewable energies: wind farms, photovoltaic parks and hybrid installations.

- Air conditioning and cooling infrastructure: high-density industrial and urban environments.